It’s the type familiar to anyone with a remote-control car or a drone, but different from the chemistry that powers a human-size electric automobile. Axial Racing asked if I wanted to test its new Yeti Trophy Truck, a 1:10 scale 4×4. My answer was yes, because my interests and hobbies essentially haven’t changed since I was 12. The Yeti arrived without a battery, so I bought a lithium-polymer.

Whilst bombing around my yard and daydreaming about the Mint 400, it occurred to me that these LiPo batteries seem pretty great: quick to charge, lots of power, lightweight. Why couldn’t you scale these suckers up? If LiPo works for a 1:10 scale car or a quadcopter, why not for the car you park in your garage? To answer that question, I called up Greg MacLean, the lead battery-cell engineer for the Chevrolet Bolt.

Advertisement – Continue Reading Below

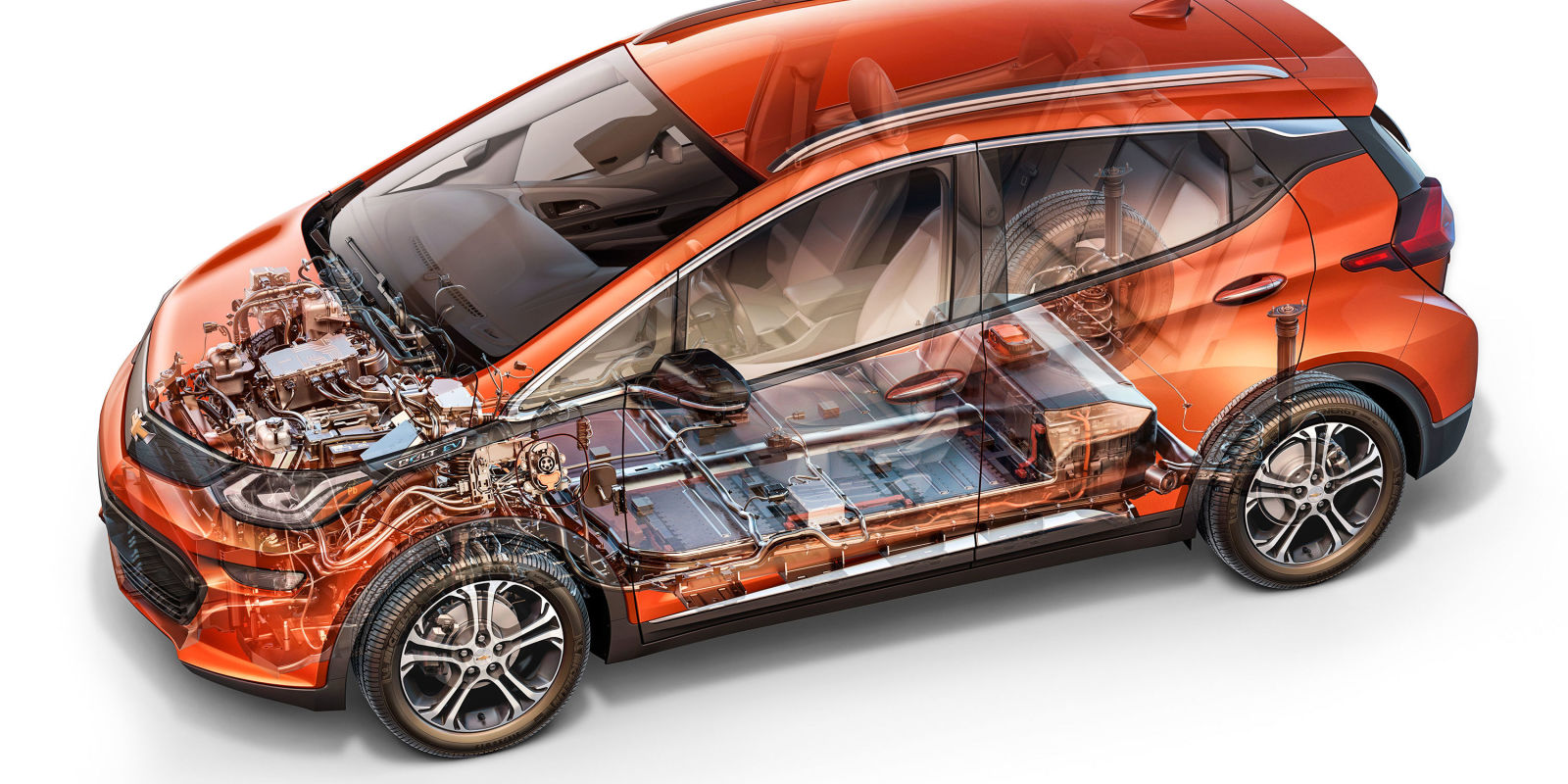

Is the Bolt battery different from the battery stuffed into the Yeti (or my MacBook)? Oh, assuredly so. Electric cars, with sophisticated software and power controllers to put out serious horsepower, have made great progress since the first Chevy Volts and Nissan Leafs hit the street six years ago. But batteries remain a challenge. There’s a reason—actually, about 100 reasons—why my toy truck’s lithium-polymer won’t power your electric road trip. Here’s why it’s not a simple fix.

Most Popular

THE ENGINEER EXPLAINS

It’s Not Just What’s on the Outside

“The term lithium-polymer is a reference to the packaging material, which is a polymer aluminum laminate. The inside is still lithium-ion, but the complete battery is dramatically different compared with a production electric car’s lithium-ion battery.”

Longevity Required

“One of the major differences between consumer electronics and automotive cells is robustness. At Chevrolet, we need to have a ten-year warranty on our packs. An RC or consumer-electronics cell is typically good for three or four years in regular use. That’s the other thing: Our vehicles use the batteries far more than an RC hobbyist will.”

Squares Fit Better

“Rather than cylindrical cells, auto-parts manufacturers generally use square-ish prismatic pouch cells. Square things fit into square boxes better. So there’s better pack density.”

Density Versus Speed

“There is a tradeoff with energy density versus fast charge capability. The faster you want to charge the battery, the lower the energy density needs to be. The cells in consumer electronics are designed to maximize energy density to squeeze the most capacity into a given space. By doing so, you compromise charge time and reliability. Even Tesla has backed off on energy density. It’s different than inside a laptop.”

Lithium-Ion Rules, for Now

“Lithium-ion isn’t just one chemistry. You can mix materials, designs, and formulas for different applications. Everybody is examining different chemistries. There’s huge potential. Lithium-ion is the winner for the foreseeable future, but you never know when a breakthrough will come. And we want to be there when it happens.”

How It Works: Lithium-Ion Batteries

Li-ion batteries have four basic components: a nickel-rich cathode, a graphite anode, a separator, and an electrolyte, the liquid through which lithium ions travel. Lithium ions are molecules that have more protons than electrons, giving them a positive charge. When you plug a battery into an outlet, electrons flow into the anode. As the electrons make the anode even more negatively charged, the lithium ions are attracted to the anode. The ions move from the cathode through the electrolyte, into the anode, increasing the battery’s voltage. The lithium ions remain in the anode until the battery is connected to something that draws current—like an electric motor. During discharge, the electrons flow out of the battery and power the motor. Once the electrons are gone, the lithium ions naturally move back to the cathode, and the battery is ready to be recharged.

<div

Recent Comments